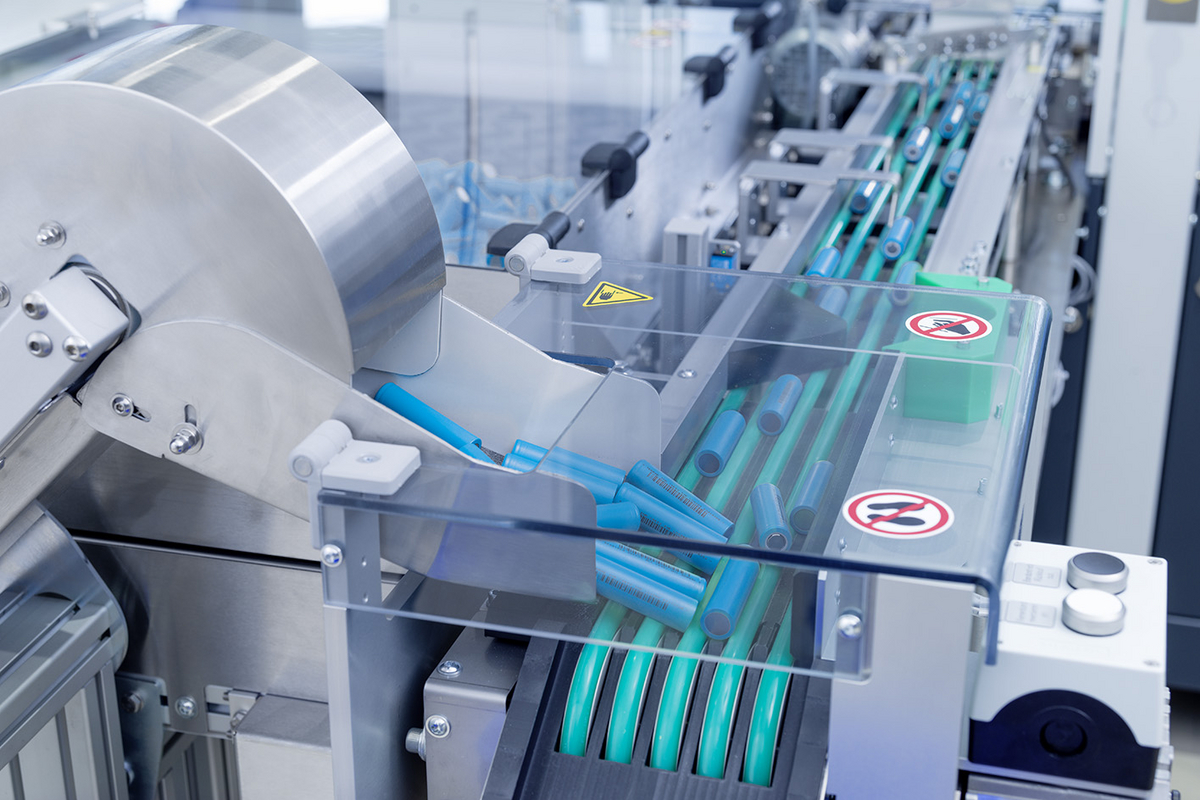

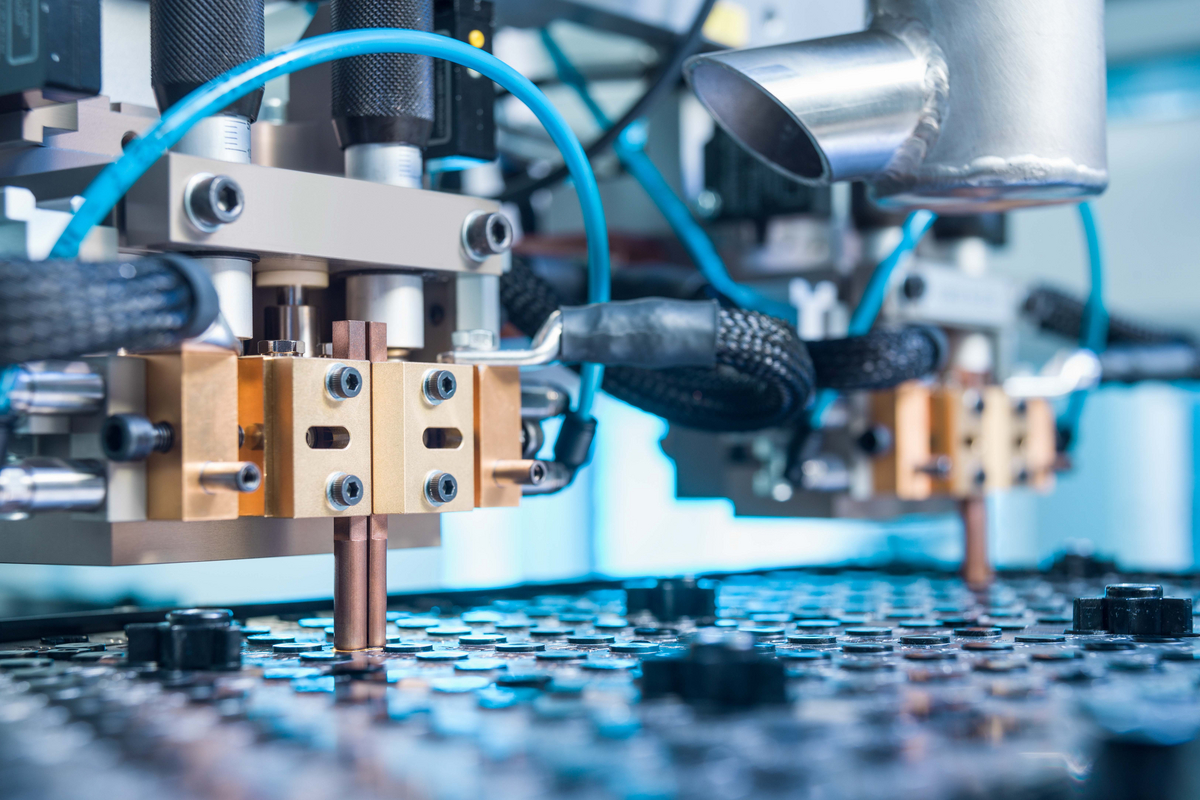

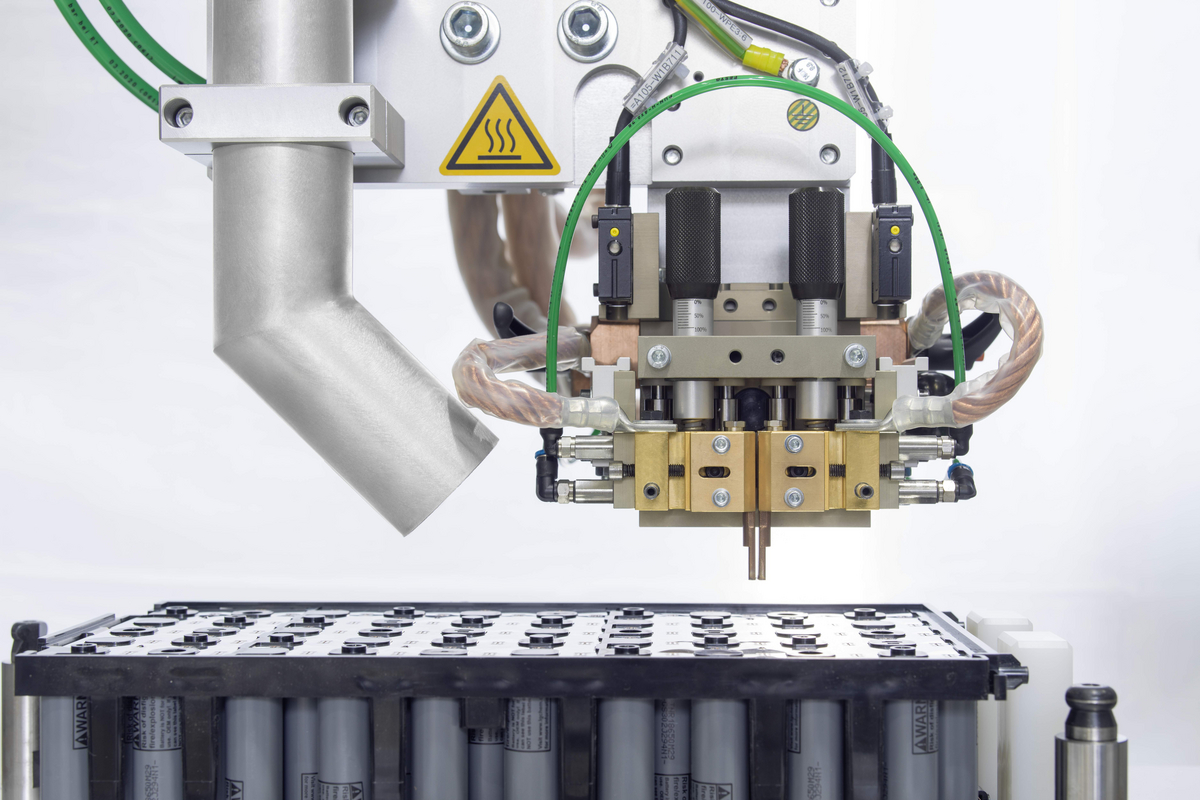

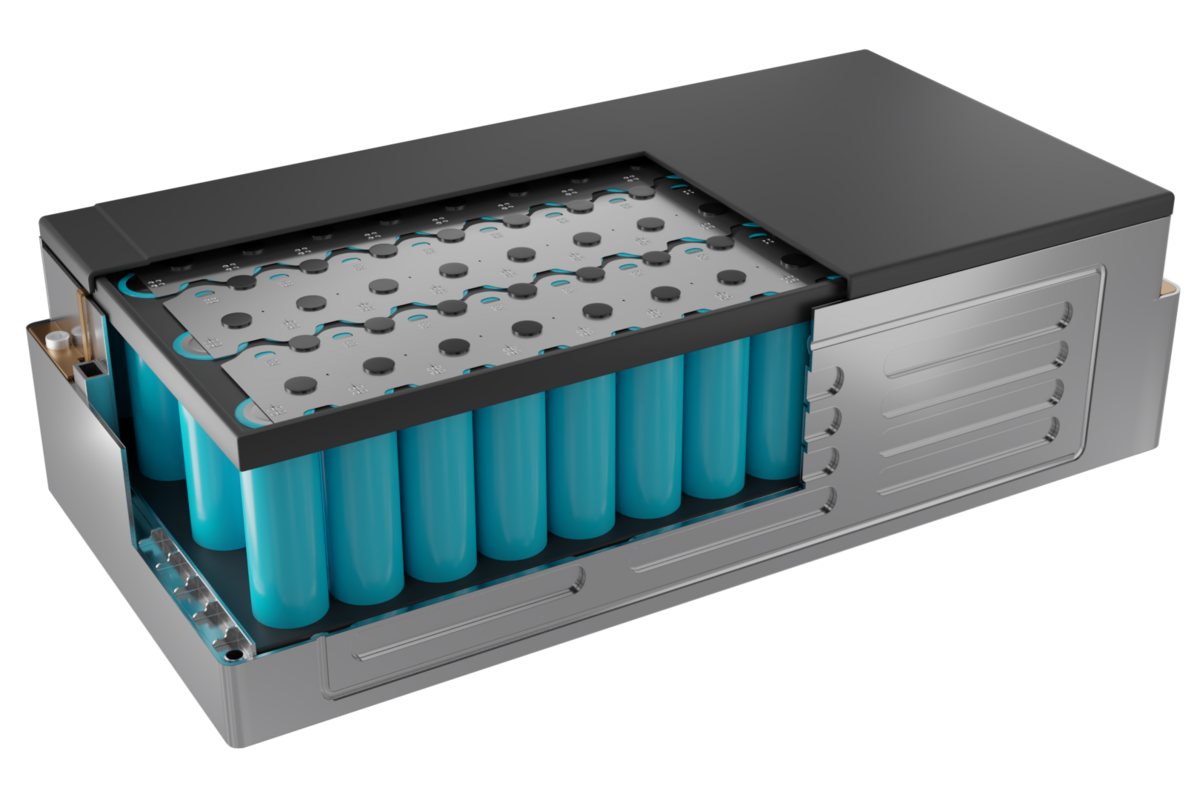

In battery module production, individual round cell batteries are quickly and precisely tested and assembled into a module. Be it a system for 18 650, 26 650, 21 700, 32 700 or 46XX round cells, our machines are dimensioned for all cell designs.

For modules based on prismatic cells, we also build smart production systems that are custom-designed to meet your requirements.

Plug and play for direct production start

Our assembly and test lines can also be used for battery modules for products like power tools and home storage systems. We provide turnkey solutions with a footprint of only 12 x 6 meters, an output of 7,200 cells per hour and system autonomy of up to 60 minutes.

Cell handling, process steps and testing steps are adjusted to customer specifications and integrated. With our broad spectrum of solutions and experience, we satisfy all requirements for the reliable production of safe and flawless battery modules.

Expertise down the line

|

Process steps in battery module production |

Visual inspections |

Electrical testing |

|---|---|---|

|

|

|

teamtechnik software and safety concepts

Your requirements are our standard

With teamsoft.RUN and teamsoft.TEST software, we enable users to monitor the quality of incoming materials, track them and run end-of-line tests. We design safety and fire protection in accordance with system operator requirements.

Read more about our software expertise.

Carsten Justus

Would you like to contact teamtechnik online?

Then use our online contact form!

HQ reception

Would you like to contact teamtechnik online?

Then use our online contact form!

News

Fairs & Events

Downloads

New Energy - Battery Production (EN)

PDF / 910.89 kB

New Energy - Battery Production (EN)

PDF / 910.89 kB