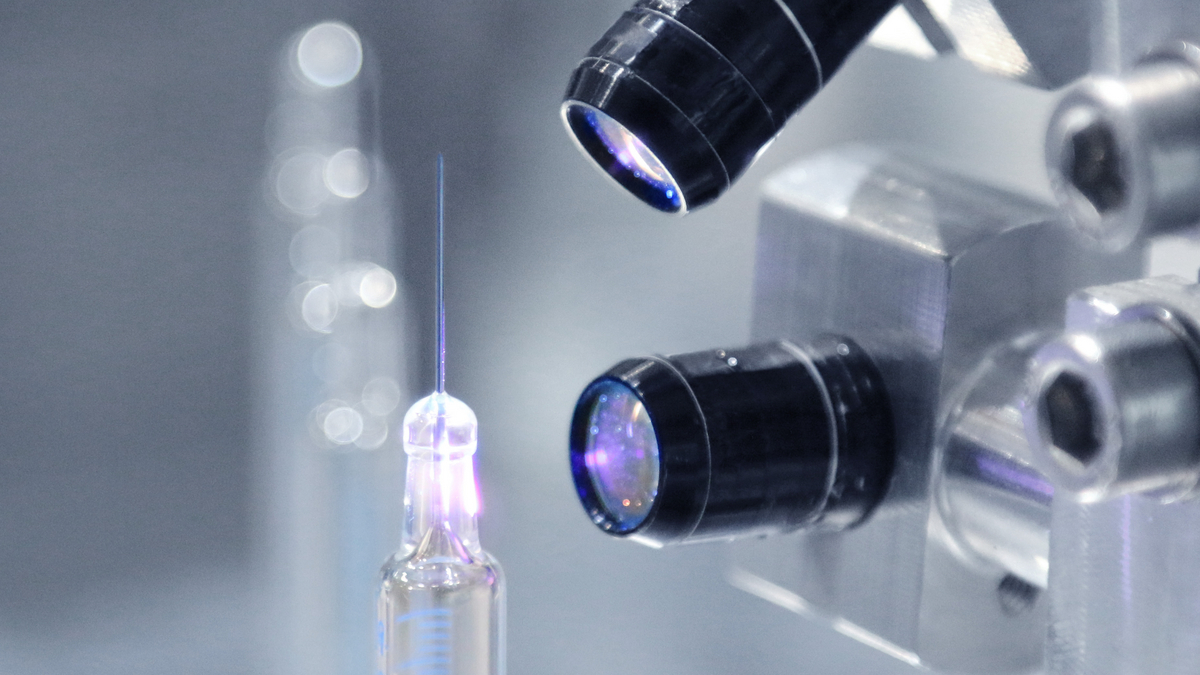

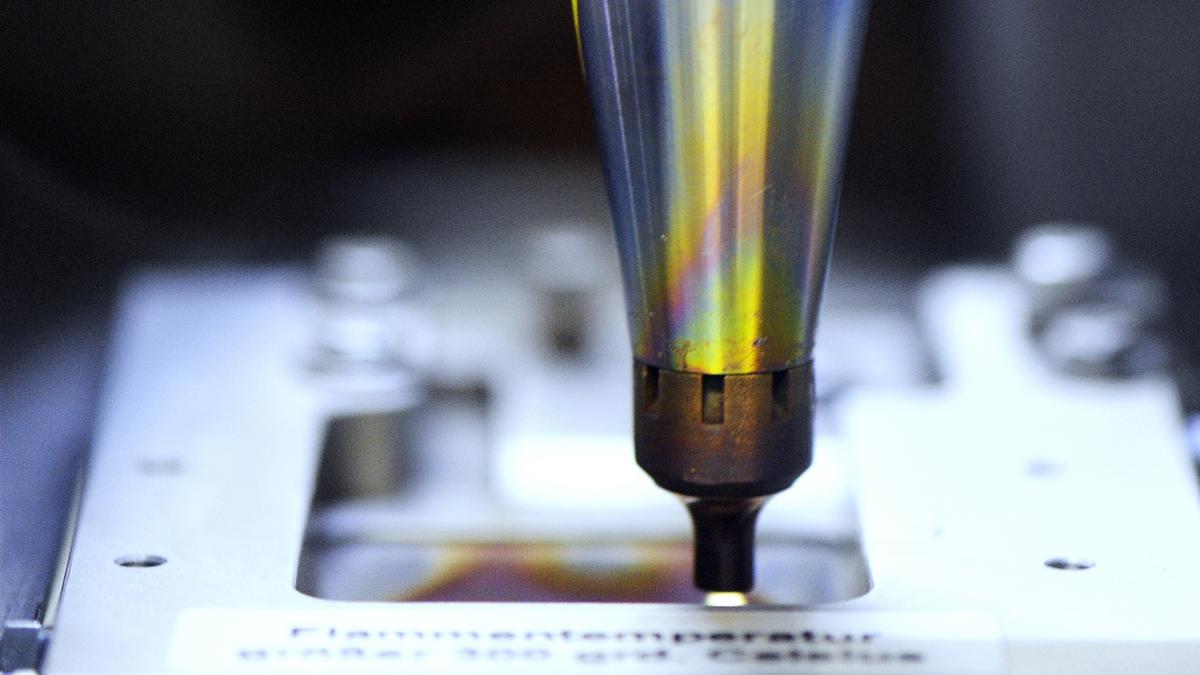

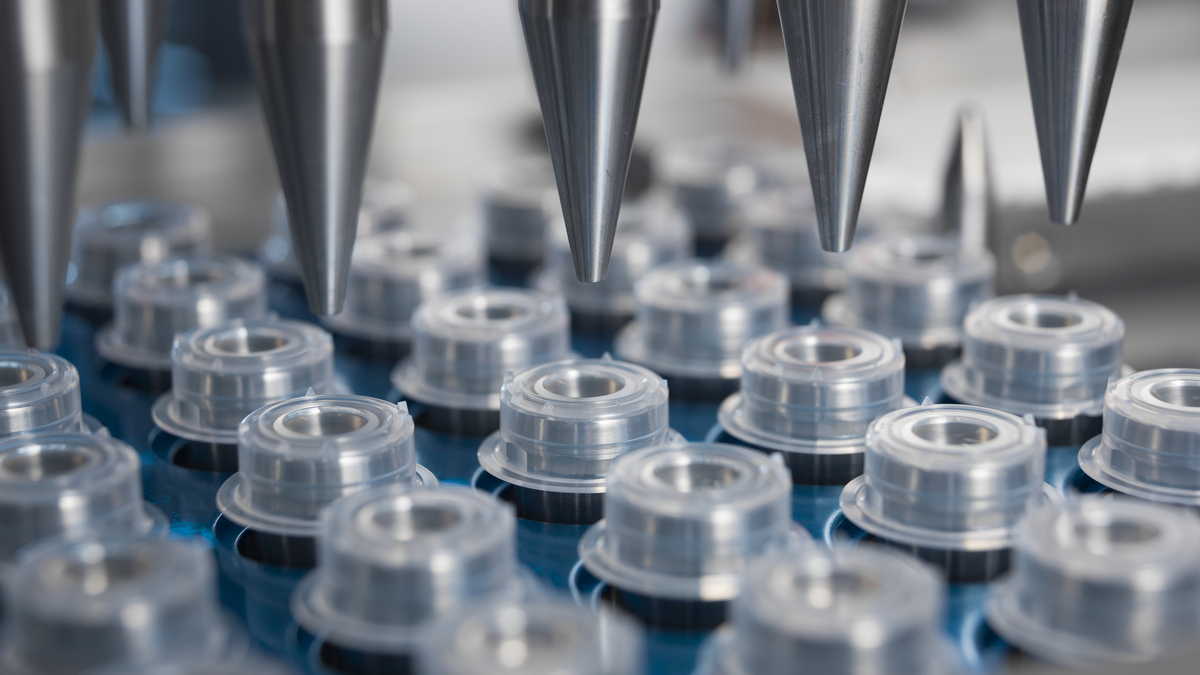

Robotic and vision processes, needle handling, functional testing, welding, gluing and joining processes, filling and dispensing technologies and much more. We have a large engineering database with extensive process technology for assembly and testing and a know-how that is always up-to-date. Our expertise at your service.

Our engineers - experienced, determined and ingenious

Experienced engineers with specific technological knowledge are needed to keep processes running stably. They also develop new and ground-breaking process solutions. For example, a cost-saving LED-based curing process. Injection systems

Our process expertise is your peace of mind

|

|

|

|

Stable processes - many proven solutions

Testing technology – our speciality right from the start

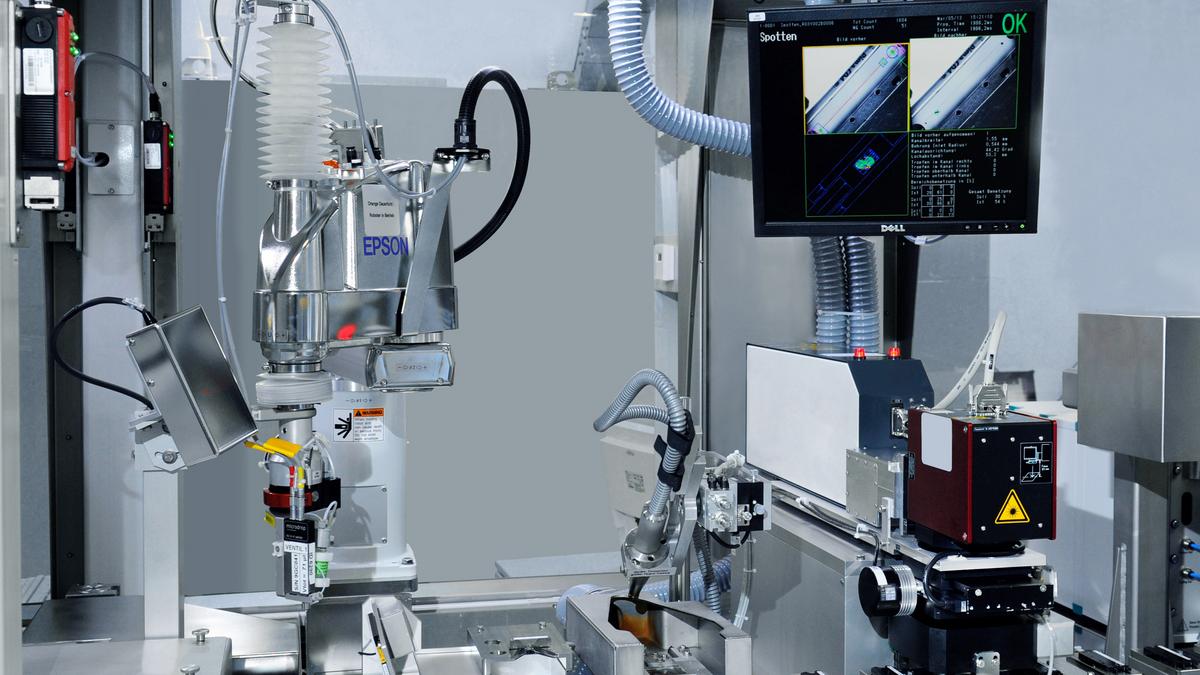

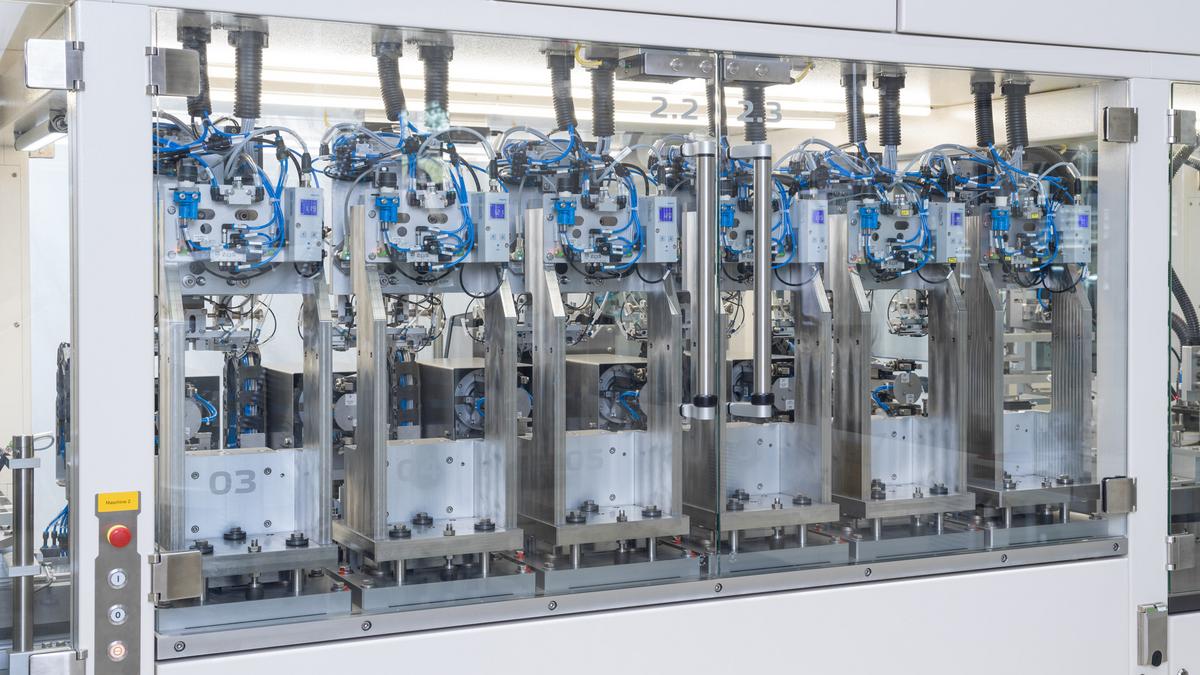

If we assemble it, we test it. The strictest regulations govern applications in the medical and pharmaceutical industries. That is why our testing experts also implement the necessary testing processes. The appropriate test parameters are developed by our software engineers.

Examples include sophisticated functional tests such as torque, force-displacement, flow testing, dynamic pressure monitoring, image processing with 3D profile scans, electrical integrity testing and many more. Injection systems

Inline testing

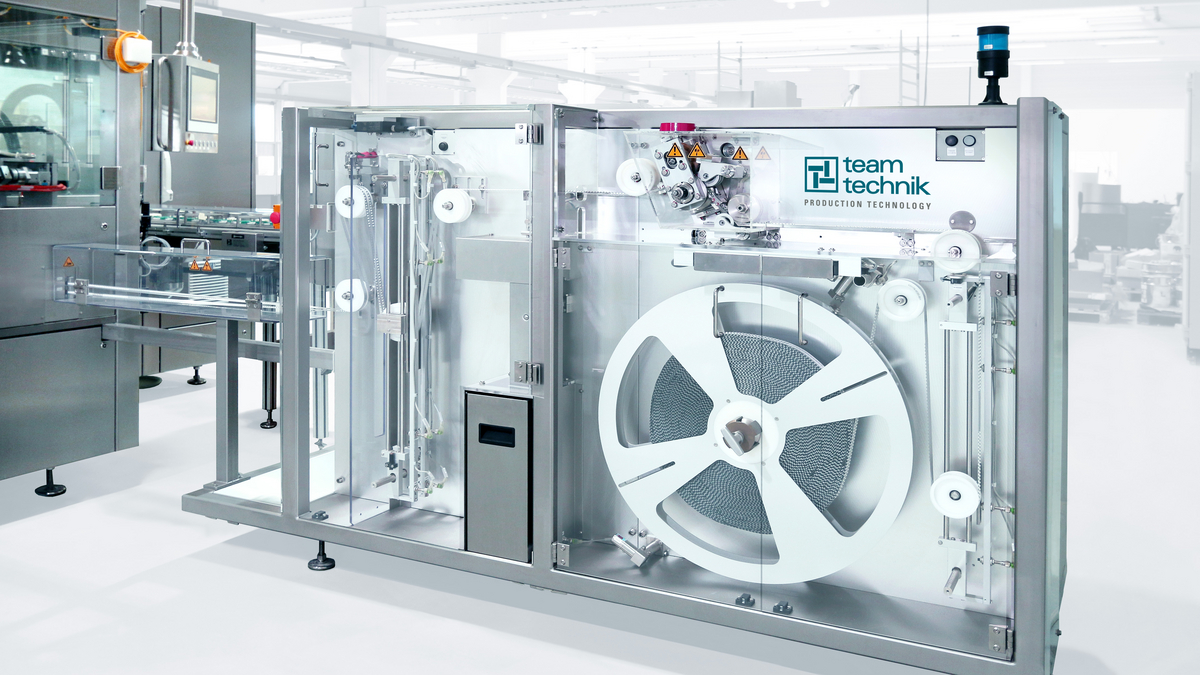

We integrate 100 per cent end-of-line testing on our TEAMED assembly platforms. The end result is a fully verified product. Only verified products leave the assembly line.

Integrated assembly and testing system

Offline TESTING

The TEAMED INJECTOR TEST automated test platform has been specially designed for the integration of complex fully automated functional tests. Ideal for your batch release tests.

Batch testing. Qualified functional testing.

Get in touch with our experts

HQ reception

Would you like to contact teamtechnik online?

Then use our online contact form!

HQ reception

Would you like to contact teamtechnik online?

Then use our online contact form!

News

Fairs & Events

Downloads

Medtech - Single Source Solutions (EN)

PDF / 686.37 kB

Medtech - Single Source Solutions (EN)

PDF / 686.37 kB

Medtech - Palletizing systems (EN)

PDF / 843.48 kB

Medtech - Palletizing systems (EN)

PDF / 843.48 kB

Medtech - Feeder Systems (EN)

PDF / 583.27 kB

Medtech - Feeder Systems (EN)

PDF / 583.27 kB

Medtech - Brochure (EN)

PDF / 1.93 MB

Medtech - Brochure (EN)

PDF / 1.93 MB