Find out more about what our associated company Kahle Automation has to offer

Kahle Automation is dedicated to providing custom automation machinery solutions for the medical device, pharmaceutical, and healthcare industries.Kahle designs and builds machines for the assembly and inspection of all types of medical devices and drug delivery products.

We master all processes from needle separation to the finished product.

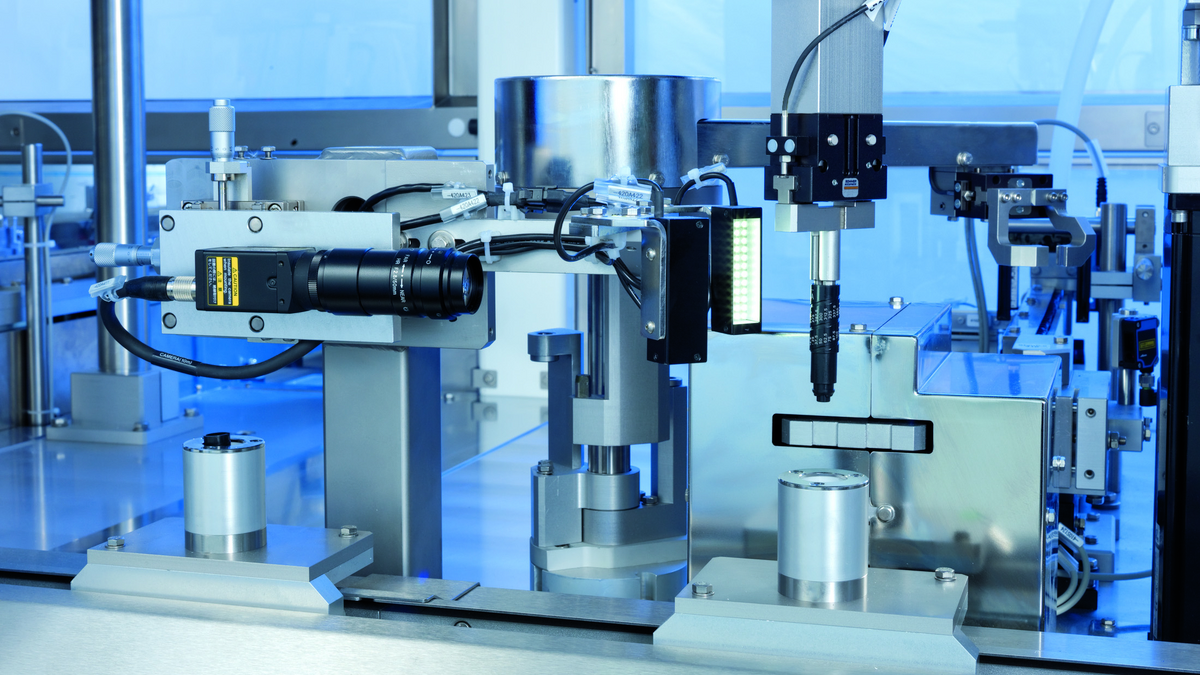

Our customers have to manufacture sophisticated injection products in large quantities. This requires highly accurate assembly and functional test processes. teamtechnik has developed a unique expertise in this area and provides reliable assembly solutions for pre-assembly, final assembly and function testing - the complete production chain from a single source.

Fully automated assembly and test system for injection pens

teamtechnik delivers everything from a single source with perfectly coordinated interfaces:

assembly, testing, software, feeding technology and palletizers

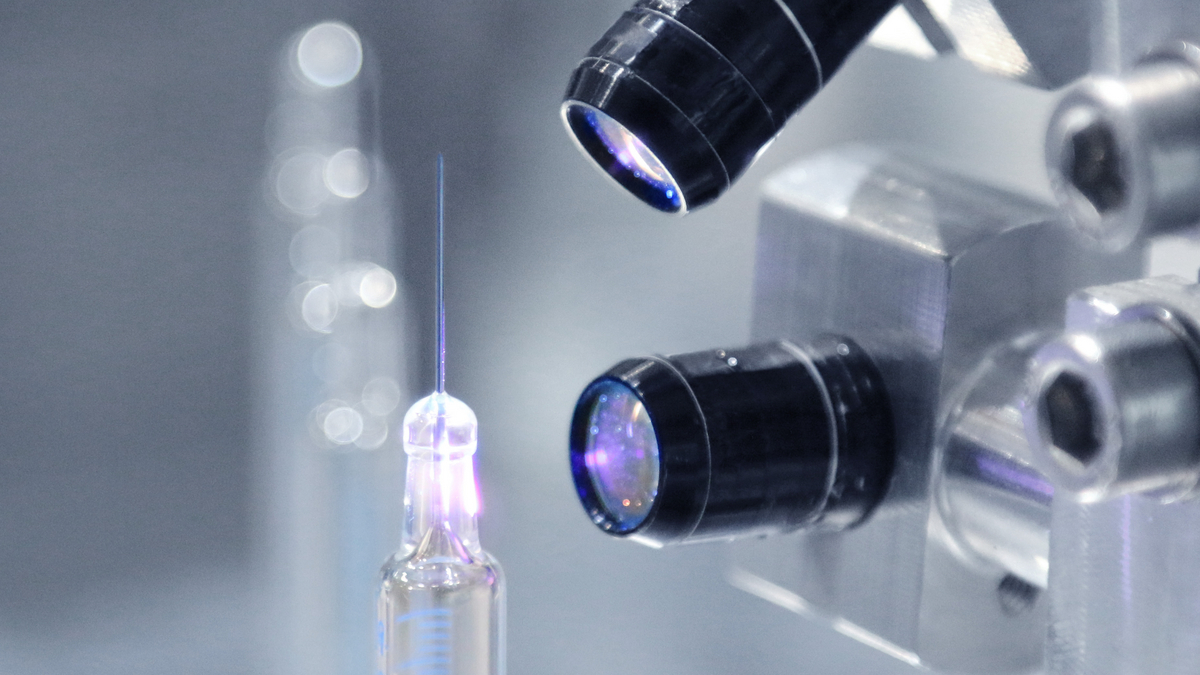

Safe handling of delicate cannulas up to gauge 34

Special magazine systems with separation technologies adapted to suit the individual cannula format are required for feeding delicate cannulas. The needles/cannulas are often rotated in order to ensure correct alignments. To do this, sensors record the micrograph for alignment and use the camera to check the needle alignment up to +/- 3 degrees. teamtechnik has the expertise required to handle even such delicate products safely.

Implemented processes

We master the critical processes for self-injection devices, pens and safety syringes: from needle separation to the finished product. At the end, our test systems verify our customers' high-quality products inline or offline.

- Glass handling

- Tip handling

- Inscription

- Volumetric glue dosing

- Needle handling

- Needle orientation

- Needle separation

- Needle bending

- Gluing (dosing, spotting)

- Curing with LED and UV

- Curing with UVA / UVC

- Camera testing

- Functional testing

- and many other processes

Reliable gluing of a cannula into a carrier

Curing adhesive with LED

Mounting and testing of scale tubes

Marking (laser, pad, inkjet printing etc.)

Pre-assembly in seconds

Assembly system for cannulas

Assembly of glass syringes with integrated camera inspection

Functional test system for pens and auto-injectors

Batch release tests – fully automated

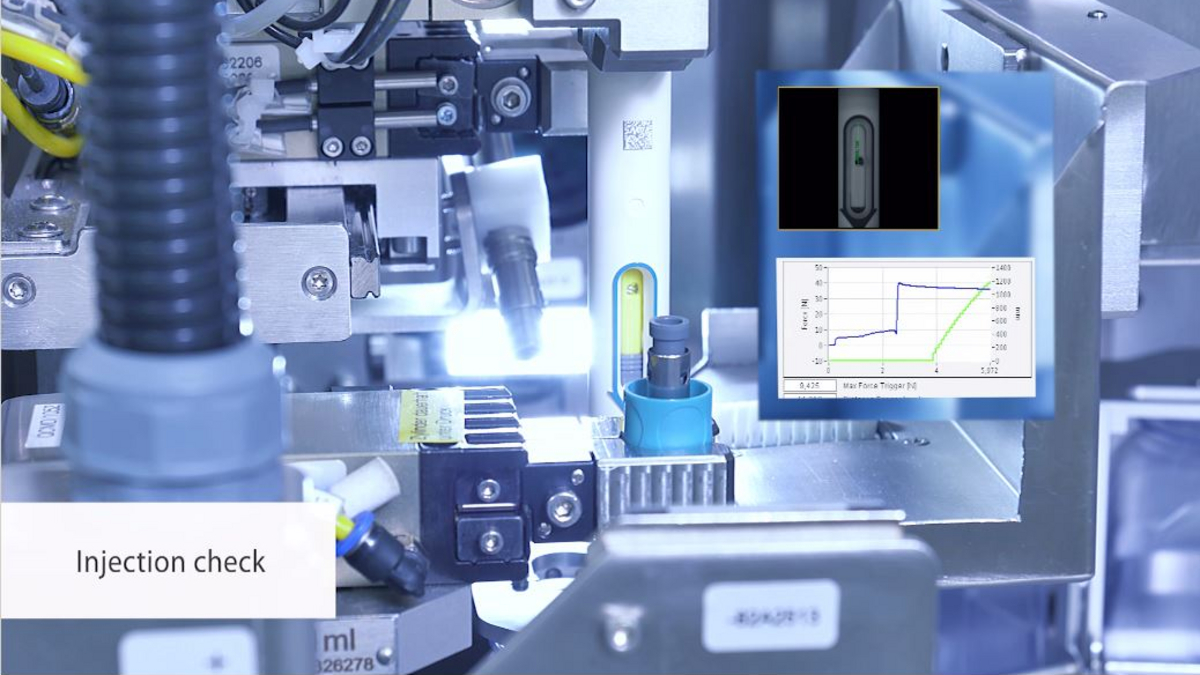

Our TEAMED Injector Test is the proven test system for injection systems. Offline tests are carried out on a batch and random basis. Automated processes thus ensure maximum safety. Only perfectly functioning injection systems pass the tests.

Tests that perfectly safeguard your products.

An example: benchmark values for the batch release test of a self-injector.

- Pull-off force needle tip ≤ 35 N

- Stroke power of the needle guard ≥ 4 N - ≤ 11 N

- Release force ≥ 5 N - ≤ 16 N

- Injection duration ≥ 2 sec - ≤17 sec

- Injection quantity ≥ 1.00 ml (≥ 1.04 g)

- Injection depth ≥ 4 mm - ≤ 8 mm

- Blocking force of the needle guard ≤ 2 mm at min. 80 N

WHAT WE TEST INLINE

Optionally, and depending on the product, we also integrate functional tests inline: Torque measurement, release force and expression stroke, force test.

With this 100% inline test, critical values are measured, displayed and securely stored and managed in our production control system.

Our applications

Why teamtechnik?

Because all services are provided by one single company:

- Assembly and testing technology

- GMP-compliant system platforms

- Feeding technology

- Palletiser/tray loader

- Software

- Qualification

Get in touch with our experts

HQ reception

Would you like to contact teamtechnik online?

Then use our online contact form!

HQ reception

Would you like to contact teamtechnik online?

Then use our online contact form!